Dicing services overview

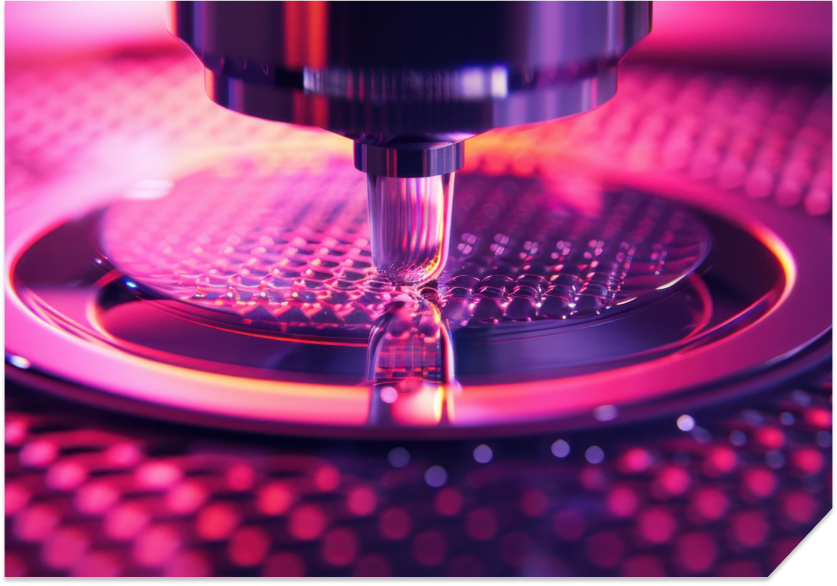

Stealth Laser

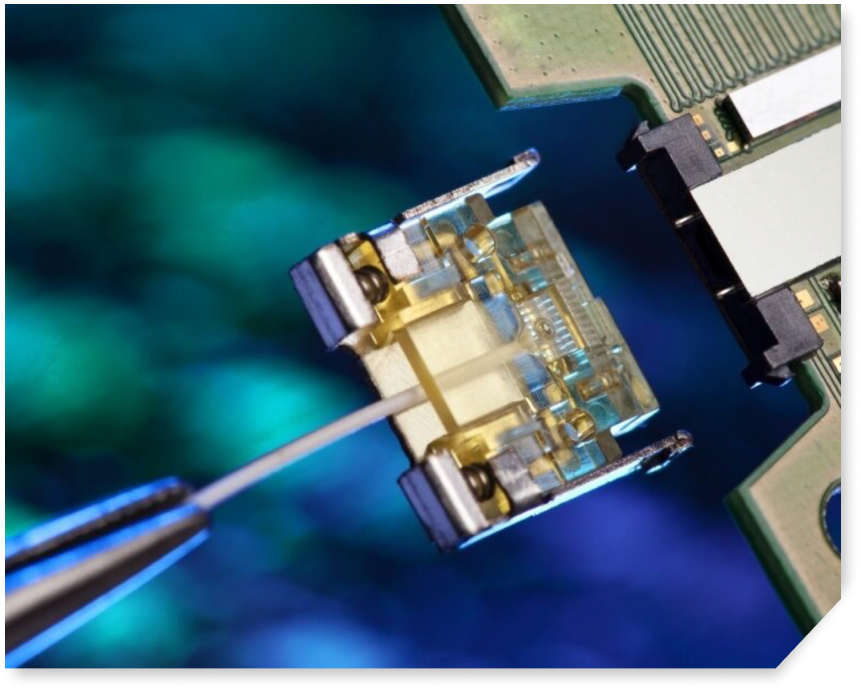

Dicing for PICs

Ultra-clean, non-contact singulation of photonic devices; minimal edge damage, optimal yield.

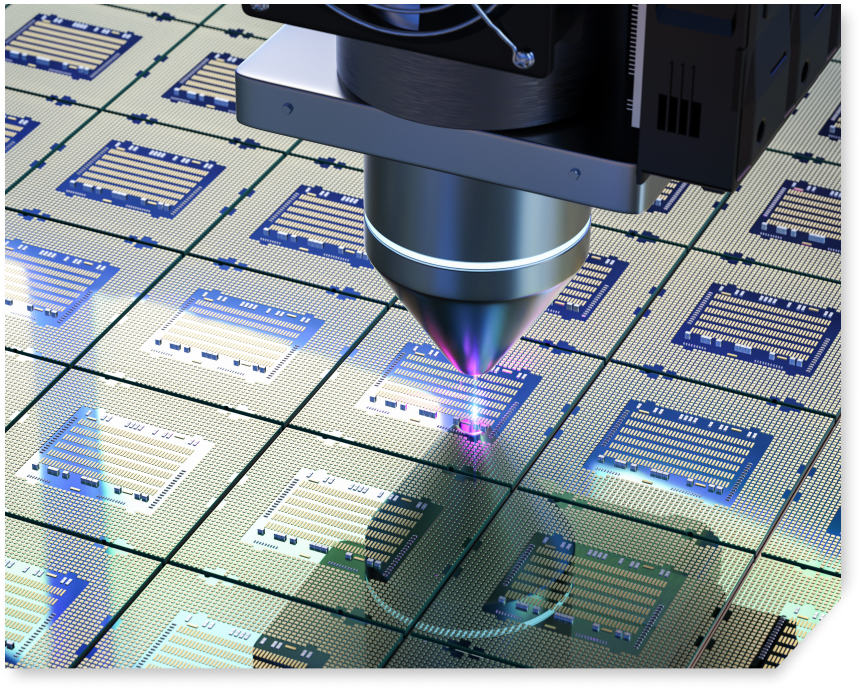

Wafer Thinning

& Polishing

Controlled thinning and CMP for smooth, reliable dies; supports silicon photonics and advanced packaging.

Standard Mechanical

Wafer Dicing

Diamond blade dicing for silicon, compound semiconductors, ceramics, and glass in volume or specialty runs.

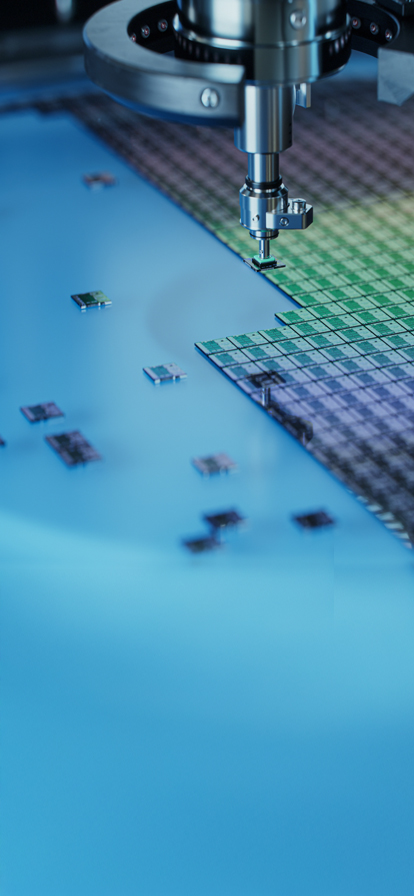

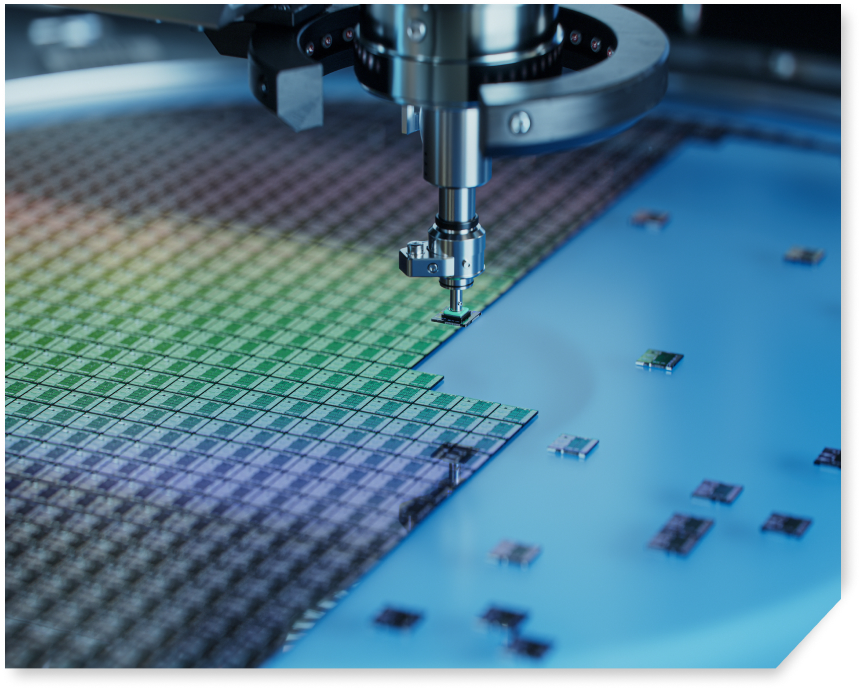

Automated AOI, Sorting,

Pick and Place

Automated Inspection, sorting, and safe pick and place for defect-free, ready-to-use dies.

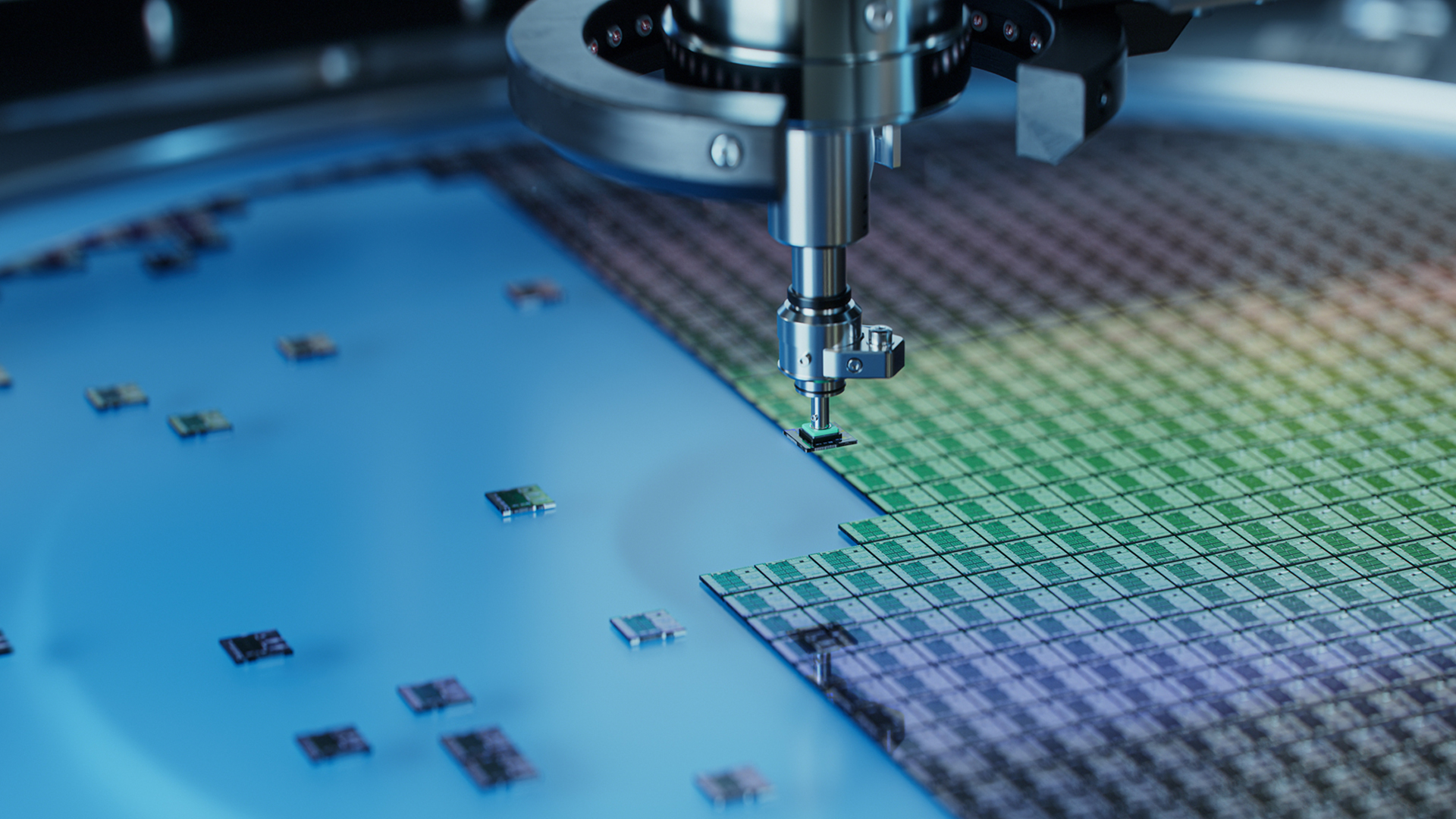

Unmatched Precision in Wafer

Dicing & Die Singulation

Dicing Process Overview

Dicing

Process Overview

Wafer Preparation & Mounting

Every process starts with ultrasonic wafer cleaning, flatness measurement, and careful mounting on dicing tape. Silitronics ensures precise alignment and minimal contamination, using anti-static environments and calibrated carriers for maximum handling safety and first-pass accuracy.

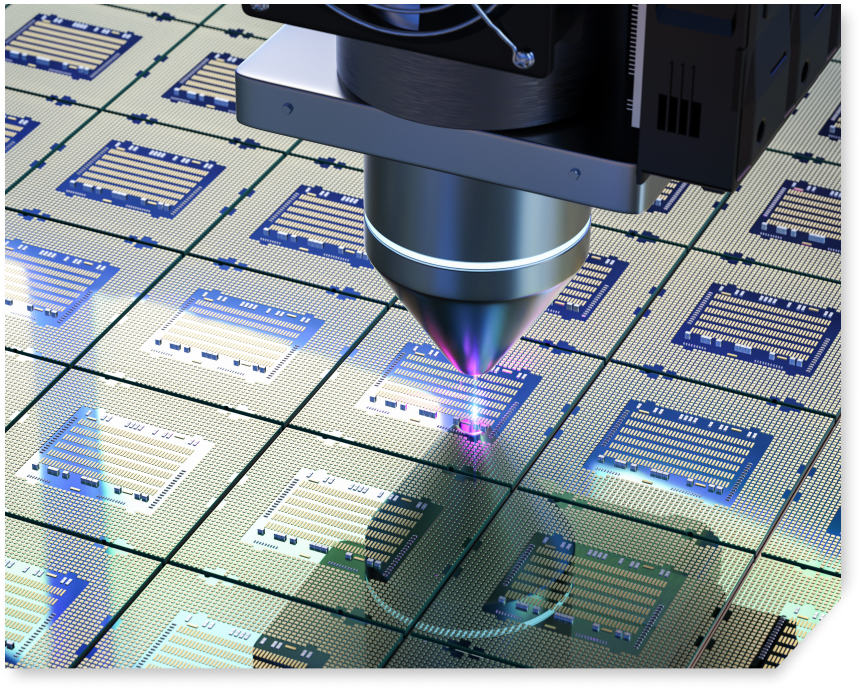

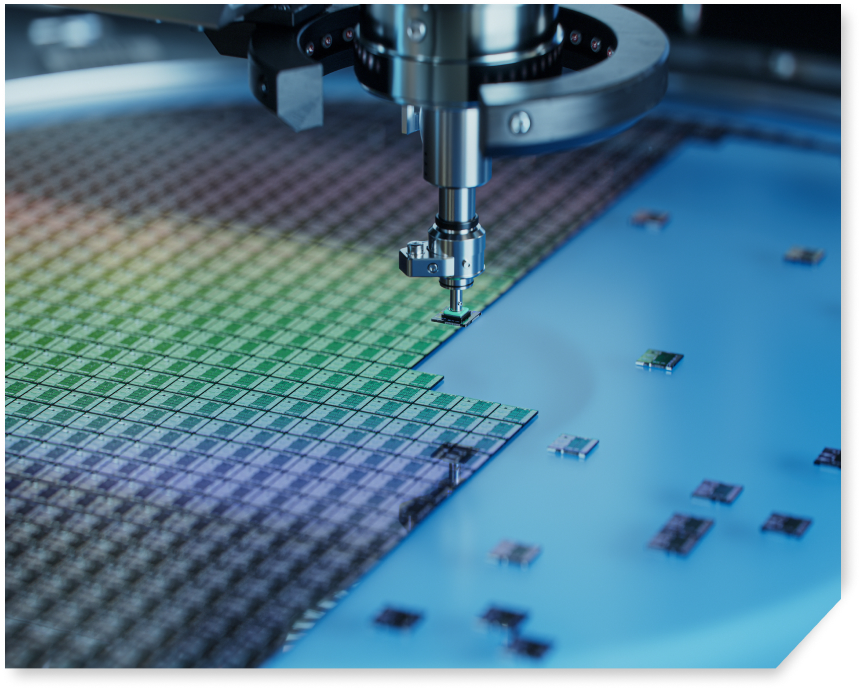

Dicing Techniques:Blade, Stealth Laser, Plasma

Silitronics tailors dicing techniques: diamond blade for standard dies, stealth laser for fragile PICs, and plasma for ultra-fine pitch. Each is optimized for kerf width, cut speed, and minimal thermal/mechanical stress. Engineers continuously monitor blade wear and laser calibration for consistent die quality, even in high-mix product runs.

Wafer Thinning & Polishing

Chemical and mechanical thinning down to sub-100µm is performed in humidity-controlled zones. Polished wafers—especially for photonics—receive additional CMP steps to achieve mirror surfaces, reducing insertion loss and supporting high-yield optical coupling.

Automated Optical Inspection (AOI) & Sorting

Post-dicing, every die undergoes AOI for cracks, chips, contamination, and dimensional accuracy. Defective dies are sorted out, while clean dies are ultrasonically cleaned, dried, and automatically sorted for traceability and next-stage fabrication.

Final Cleaning & Packaging

Finished dies receive anti-static handling, laser marking, and custom tray or tape-and-reel packaging, all designed for shipment integrity and downstream assembly reliability.

Dicing Services Spectrum

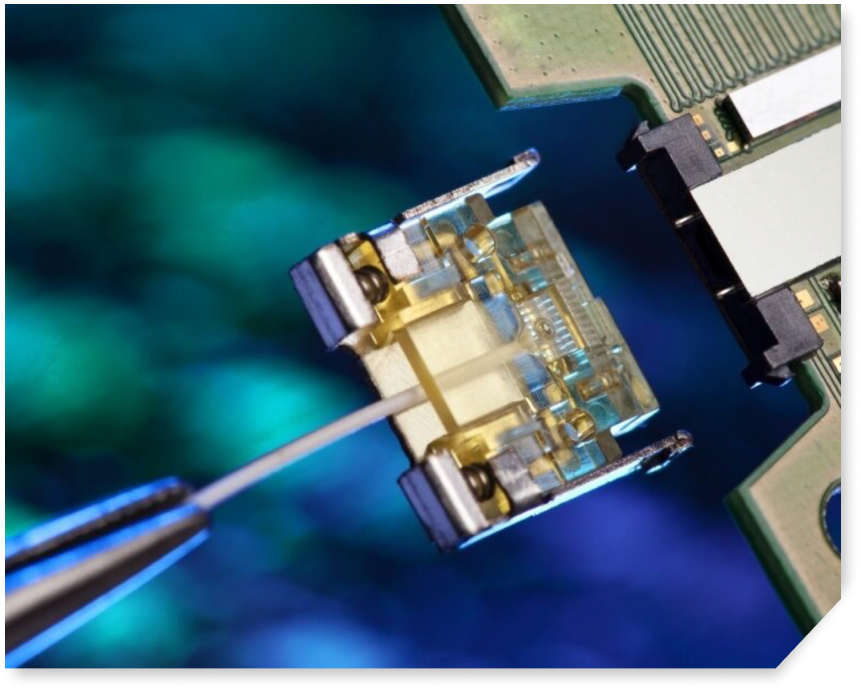

Stealth Laser Dicing for Photonic

Integrated Circuits (PICs)

Stealth laser enables non-contact singulation

of PICs, minimizing

stress

and

edge

damage for

high-performance and ultra-sensitive devices.

Silitronics’

proprietary process delivers top

yield and edge cleanliness, critical

for

data

and optical communications.

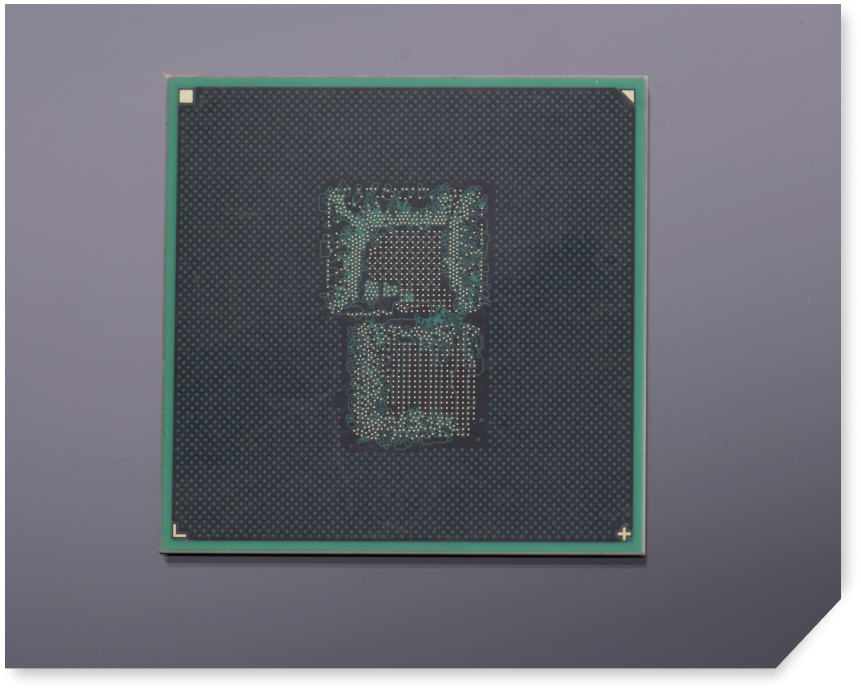

Standard Wafer Dicing for

Semiconductor and

Compound

Materials

Diamond blade dicing suited for silicon, GaAs,

ceramic, and

glass

wafers, with proven

reliability and scalable throughput.

Customizable

blade

selection and process

parameters allow for tailored solutions for

unique

device

requirements.

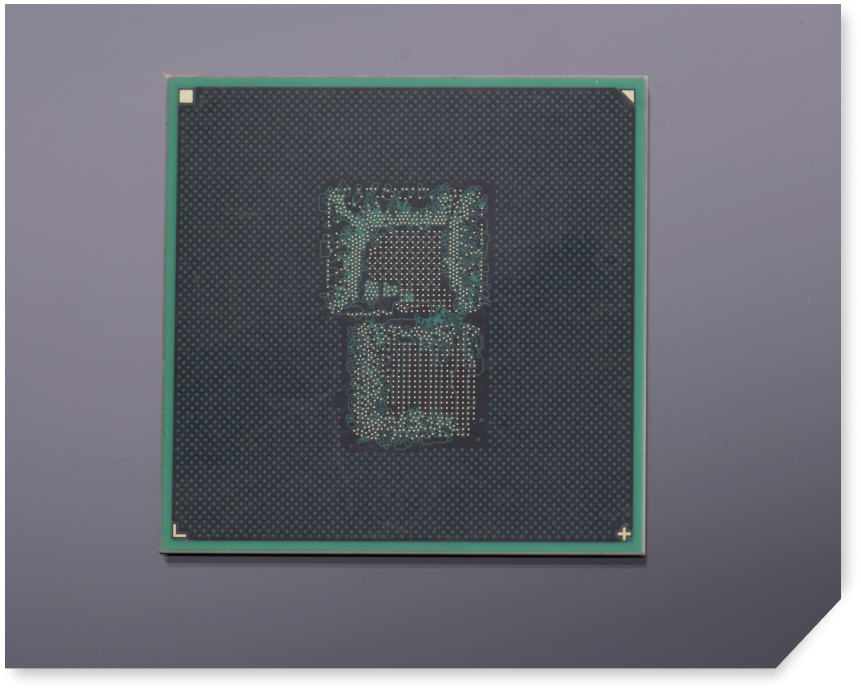

Wafer Thinning and Polishing

Controlled thinning for high-speed logic,

photonics, and MEMS

platforms, enabling thinner

devices with improved thermal and

mechanical

performance. Post-thinning CMP ensures

consistently smooth surfaces,

optimized

for

assembly, optics, and device longevity.

Automated AOI, Sorting,

and Final Packaging

High-resolution inspection, binning, and safe

packaging

guarantee

each die is defect-free and

production-ready. Silitronics’ QC-driven

approach

provides clear traceability across

every wafer, batch, and customer

order.

Dicing Services

Spectrum

Stealth Laser Dicing for Photonic

Integrated Circuits (PICs)

Stealth laser enables non-contact

singulation of PICs,

minimizing

stress and

edge damage for high-performance and ultra-

sensitive

devices.

Silitronics’ proprietary

process delivers top yield and edge

cleanliness,

critical for data and optical

communications.

Standard Wafer Dicing for

Semiconductor and

Compound

Materials

Diamond blade dicing suited for silicon, GaAs,

ceramic, and

glass

wafers, with proven

reliability and scalable throughput.

Customizable

blade

selection and process

parameters allow for tailored solutions for

unique

device

requirements.

Wafer Thinning and Polishing

Controlled thinning for high-speed logic,

photonics, and

MEMS

platforms, enabling

thinner devices with improved thermal and

mechanical

performance. Post-thinning CMP

ensures consistently smooth surfaces,

optimized

for assembly, optics, and device

longevity.

Automated AOI, Sorting, and

Final Packaging

High-resolution inspection, binning,

and safe packaging

guarantee

each die is

defect-free and production-ready.

Silitronics’ QC-driven

approach

provides

clear traceability across every wafer,

batch, and customer

order.

Our Services Spectrum

Precision-Driven Design for

Next-Gen Semiconductor &

Photonic Packaging

From concept to layout, our advanced design expertise ensures seamless integration of chips, substrates, and interconnects. We optimize signal integrity, power efficiency, and thermal performance to meet the demands of AI accelerators, quantum computing, and high-speed photonic systems. With deep engineering insights, we design scalable, high-reliability solutions for the future.

LEARN MORE

Fabrication for Advanced

Semiconductor & Photonic Packaging

Our state-of-the-art fabrication facility delivers high-precision multi-layer substrates tailored for AI, HPC, and Silicon Photonics. With expertise in organic and ceramic substrates, fine-pitch interconnects, and high-density integration, we ensure superior reliability, scalability, and manufacturing excellence. From prototypes to high-volume production, we bring innovation to life with precision.

LEARN MORE

High-Precision Wafer Dicing

We deliver advanced wafer dicing using precision blade and laser technologies to ensure clean die separation with minimal chipping. Optimized for high yield and low particle contamination, our dicing supports next-gen semiconductor packaging and performance.

LEARN MORE

Powering the Future at the

Speed of Light with Photonics

Silicon Photonics is transforming high-speed computing, AI clusters, and next-gen data transfer. Our expertise in sub-micron active alignment, optical integration, and high-bandwidth packaging ensures low-latency, energy-efficient performance. From LiDAR to AI-driven interconnects, we deliver cutting-edge photonics solutions that push the limits of speed, scalability, and efficiency.

LEARN MORE

Seamless Assembly for High-Precision

Semiconductor & Photonic Packaging

Our cutting-edge assembly expertise ensures precise chip-to-package integration with industry-leading sub-micron active alignment, high-density interconnects, and heterogeneous integration. We specialize in complex optical and electronic assemblies for AI accelerators, 5G networks, and next-gen computing, delivering high-reliability solutions that optimize performance and reduce time to market.

LEARN MORE

Breakthrough Chiplet Integration for

Scalable, Next-Gen Systems

Silitronics empowers the future of electronics with advanced chiplet integration—merging diverse dies on precision-engineered interposers for optimal signal, power, and thermal performance. Our expertise in modular floor planning and heterogeneous assembly accelerates high-bandwidth, low-latency connectivity that’s essential for AI, HPC, and 5G. From concept design to rigorous validation, Silitronics helps customers bring complex systems to market—faster, smarter, and more reliably.

LEARN MOREOur Services Spectrum

Precision-Driven Design for

Next-Gen Semiconductor

& Photonic

Packaging

From concept to layout, our advanced design expertise ensures seamless integration of chips, substrates, and interconnects. We optimize signal integrity, power efficiency, and thermal performance to meet the demands of AI accelerators, quantum computing, and high-speed photonic systems. With deep engineering insights, we design scalable, high-reliability solutions for the future.

LEARN MORE

Fabrication for AdvancedSemiconductor & Photonic Packaging

Our state-of-the-art fabrication facility delivers high-precision multi-layer substrates tailored for AI, HPC, and Silicon Photonics. With expertise in organic and ceramic substrates, fine-pitch interconnects, and high-density integration, we ensure superior reliability, scalability, and manufacturing excellence. From prototypes to high-volume production, we bring innovation to life with precision.

LEARN MORE

High-Precision Wafer Dicing

We deliver advanced wafer dicing using precision blade and laser technologies to ensure clean die separation with minimal chipping. Optimized for high yield and low particle contamination, our dicing supports next-gen semiconductor packaging and performance.

LEARN MORE

Powering the Future at the Speed of Light with Photonics

Silicon Photonics is transforming high-speed computing, AI clusters, and next-gen data transfer. Our expertise in sub-micron active alignment, optical integration, and high-bandwidth packaging ensures low-latency, energy-efficient performance. From LiDAR to AI-driven interconnects, we deliver cutting-edge photonics solutions that push the limits of speed, scalability, and efficiency.

LEARN MORE

Seamless Assembly for High-Precision Semiconductor & Photonic Packaging

Our cutting-edge assembly expertise ensures precise chip-to-package integration with industry-leading sub-micron active alignment, high-density interconnects, and heterogeneous integration. We specialize in complex optical and electronic assemblies for AI accelerators, 5G networks, and next-gen computing, delivering high-reliability solutions that optimize performance and reduce time to market.

LEARN MORE

Breakthrough Chiplet Integration for Scalable, Next-Gen Systems

Silitronics empowers the future of electronics with advanced chiplet integration—merging diverse dies on precision-engineered interposers for optimal signal, power, and thermal performance. Our expertise in modular floor planning and heterogeneous assembly accelerates high-bandwidth, low-latency connectivity that’s essential for AI, HPC, and 5G. From concept design to rigorous validation, Silitronics helps customers bring complex systems to market—faster, smarter, and more reliably.

LEARN MORECase Studies

Flawless execution, rapid prototyping, and first-pass success for cutting-edge automotive LiDAR technology.

First-pass success, rapid prototyping, and precision execution for breakthrough imaging technology.

Download case studyAccelerating Innovation in 4K Live Streaming & Gaming Cameras

First-pass success, rapid prototyping, and precision execution for breakthrough imaging technology.

Download case studyHigh-Yield, High-Precision IC Packaging for 5G & RF Innovation

Reliable, flexible, and high-performance IC packaging solutions, ensuring uninterrupted supply and exceptional quality.

Download case studyGet in touch

Interested in our end-to-end advanced semiconductor and photonics (PIC) packaging solutions?

Share your details for an expert connect.