Fabrication services overview

Organic Build-Up

Substrates

High-speed multilayer build-up with fine

line/space, thin core, and embedded

passives

for custom applications.

HDI & Fine-Pitch

Substrate Design

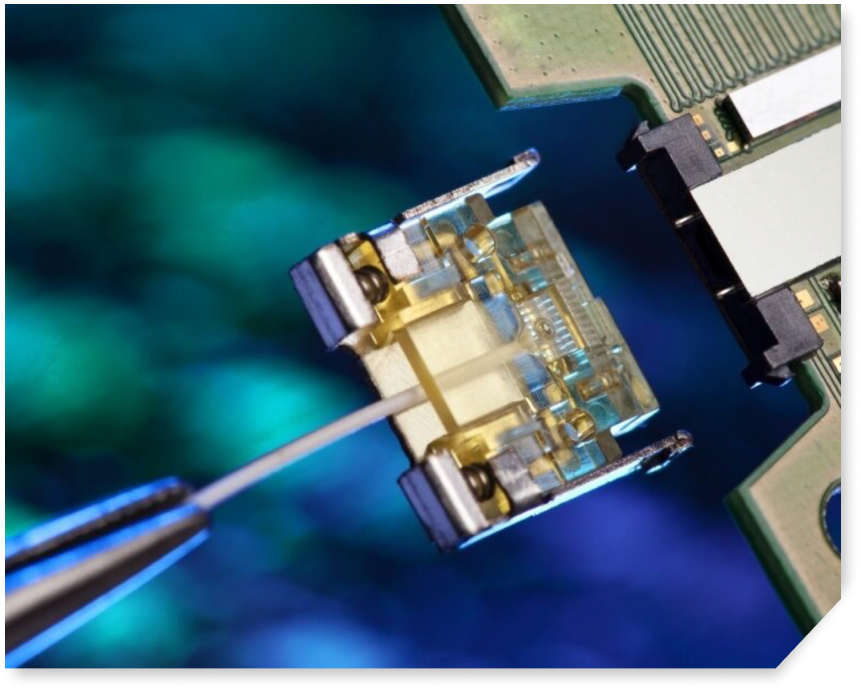

State-of-the-art microvia and blind/buried via processing for next-gen integration, SiP,and photonics modules.

Ceramic Substrates

(HTCC/LTCC)

Precision ceramics with thick film metallization and advanced tape lamination for wireless, RF, and harsh environments.

Rapid Prototyping &

Volume Manufacturing

Agile sampling and scalable production—high yield from first prototype to full deployment.

Pioneering the Future of Advanced

Substrate Manufacturing

Fabrication Process Overview

Fabrication Process Overview

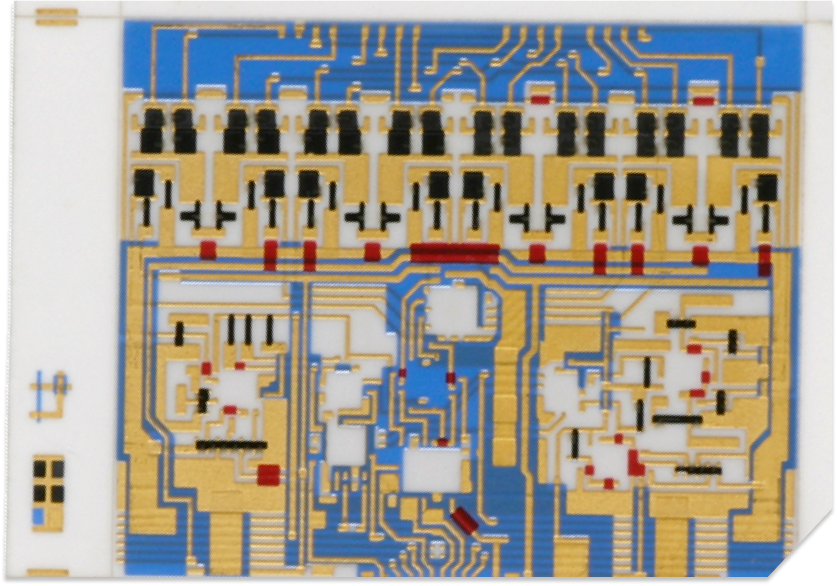

Material Selection & Lamination

Each substrate starts with careful material selection—BT, ABF, or ceramic bases tailored for electrical, thermal, and mechanical needs. Sophisticated lamination controls produce uniform core thickness and optimal dielectric properties, forming the foundation for reliable, high-density interconnects in complex stack-ups.

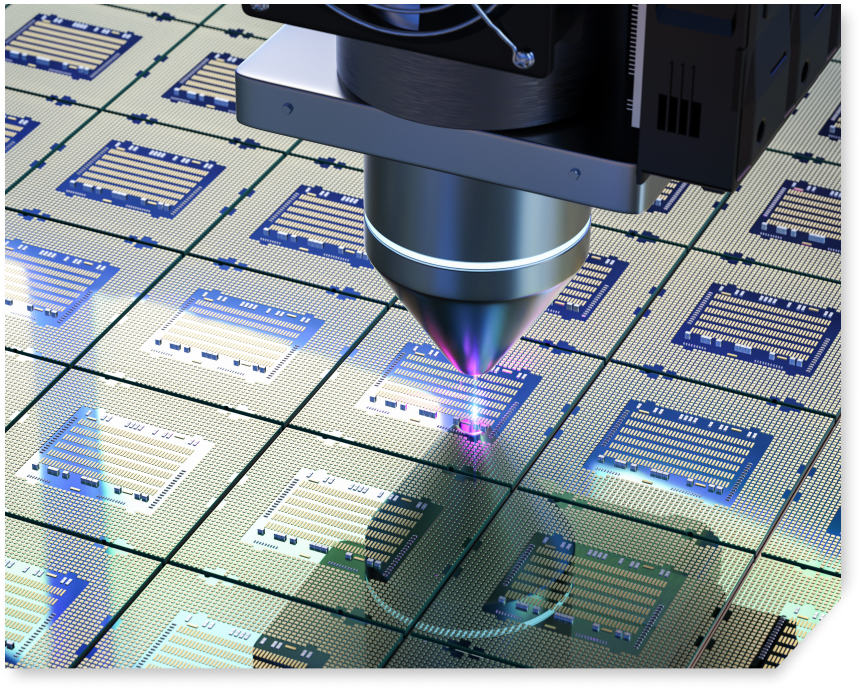

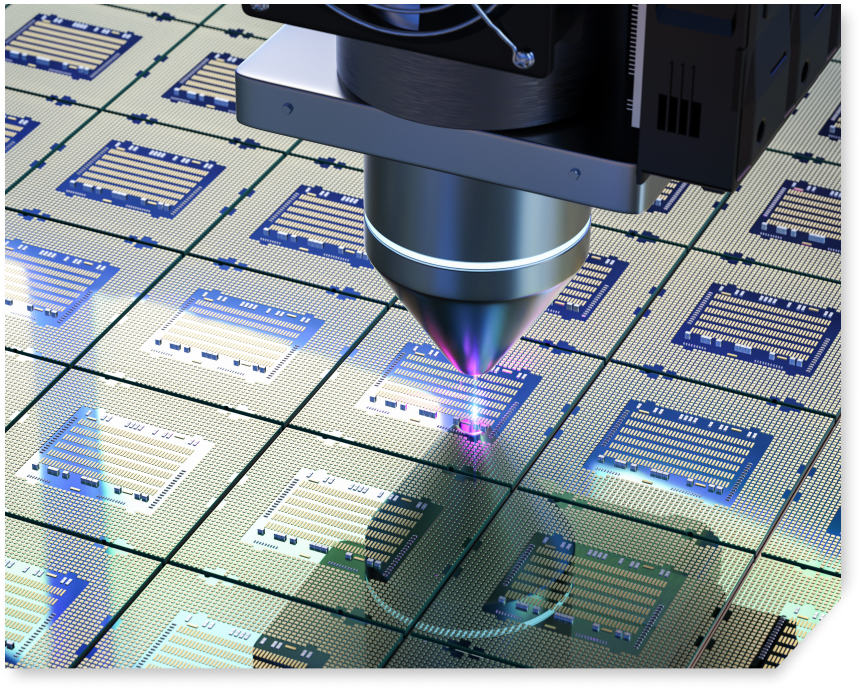

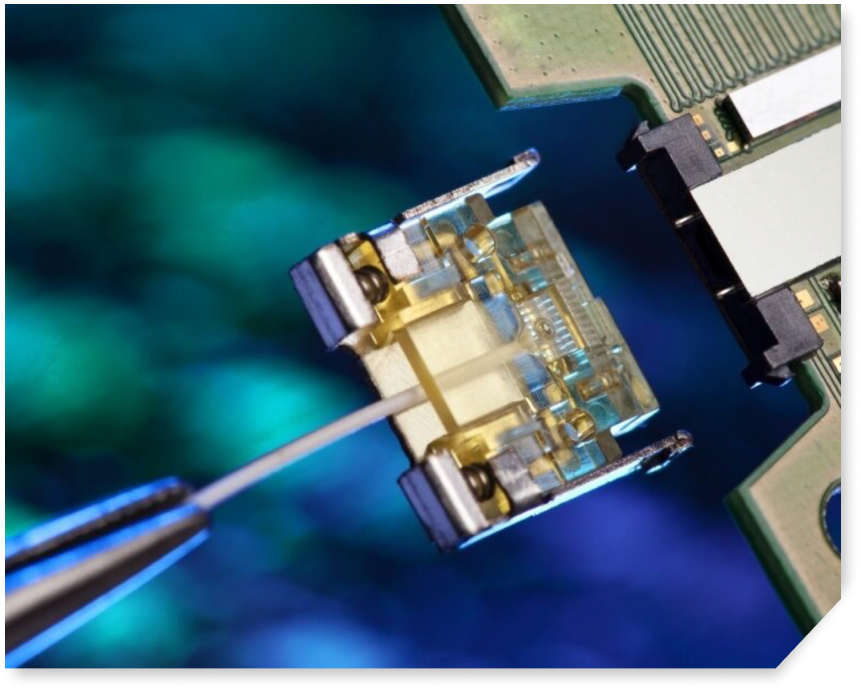

Microvia Formation & Drilling

Utilizing both mechanical and precision laser drilling, Silitronics produces microvias at sub-15µm sizes for dense layouts. Advanced laser techniques allow formation of blind/buried vias in multilayer boards, critical for HDI and next-gen designs. Every drill cycle is monitored for registration and via integrity to prevent signal loss.

Define Architecture

Dry film lamination and photolithography precisely create circuit features down to 10/10 µm. High-quality copper plating ensures controlled impedance and robust signal performance, while state-of-the-art etching selectively removes unwanted metal. The result is consistently accurate trace geometry in every substrate.

Surface Treatment & AOI

Substrates receive premium finishes including ENIG, ENEPIG and OSP, supporting solderability and corrosion resistance. Automated Optical Inspection (AOI) and electrical testing rigorously validate layer registration and circuit continuity, guaranteeing process reliability and readiness for advanced assembly.

Profiling, Cutting & Final QA

Each substrate is precisely profiled and cut to custom dimensions, undergoes final inspection, and receives full process documentation to aid traceability and support regulatory requirements. This end-to-end approach eliminates hidden defects and assures high-yield downstream integration.

Profiling, Cutting & Final QA

Each substrate is precisely profiled and cut to custom dimensions, undergoes final inspection, and receives full process documentation to aid traceability and support regulatory requirements. This end-to-end approach eliminates hidden defects and assures high-yield downstream integration.

Fabrication Services Spectrum

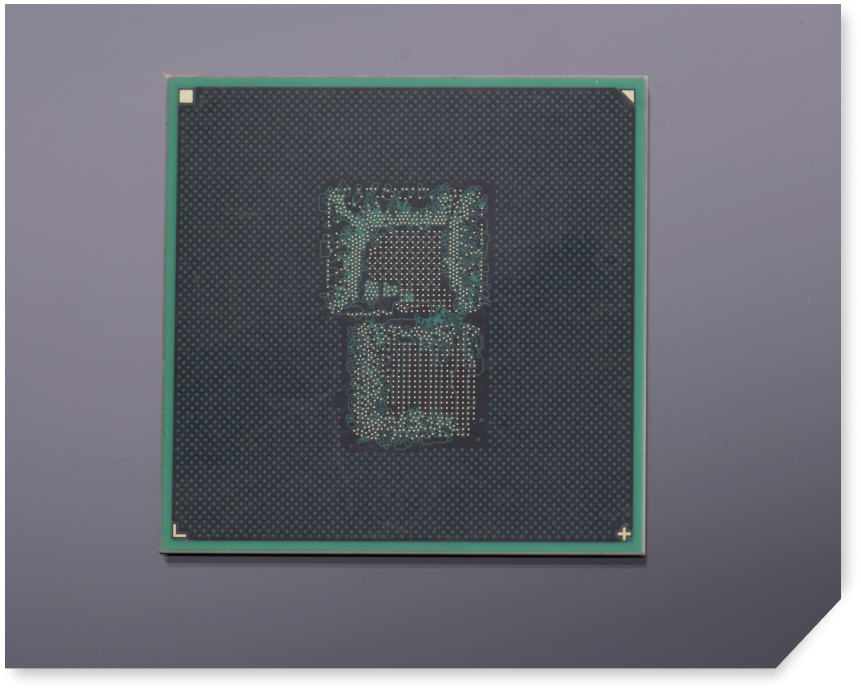

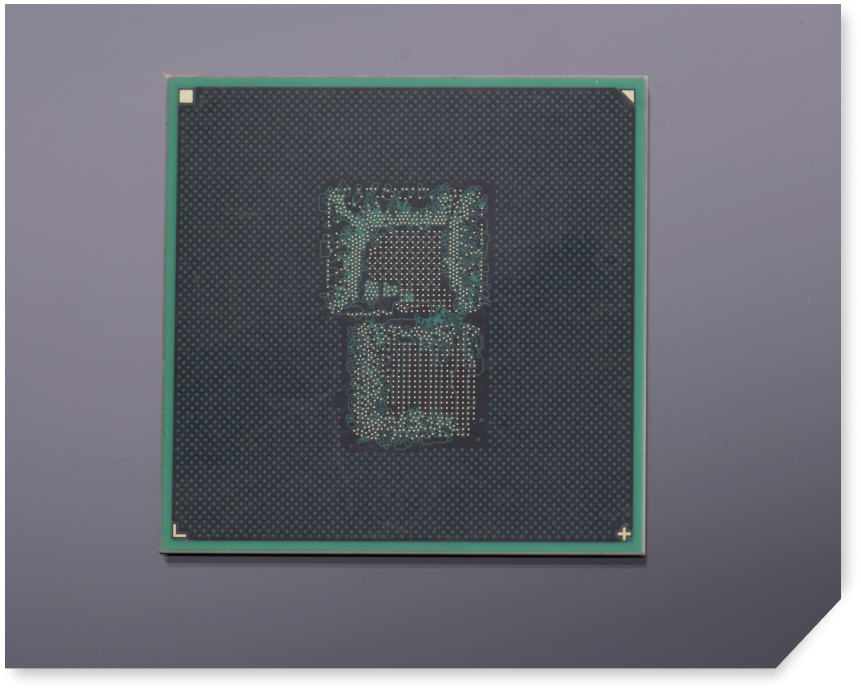

Organic Build-Up Substrates

High-speed multilayer build-up substrates with fine line/space, thin core, and embedded passives. Silitronics provides full customization for networking, AI, and medical platforms, ensuring superior signal integrity and thermal handling, from rapid prototyping to high-volume production.

Ceramic Substrates

(Etch Thick Film, HTCC, LTCC)

Specializing in robust ceramics for wireless, sensor, and RF applications. Employing advanced tape lamination and metallization processes, Silitronics delivers ceramics with precise conductor layouts, superior environmental resilience, and polished surfaces for optimum device performance.

HDI & Fine-Pitch Substrate Design

State-of-the-art microvia, blind/buried via, and tightly controlled copper thickness enable next-gen integration for silicon photonics, SiP, and multichip modules. Designed for high reliability, superior SI/PI, and production scalability.

Rapid Prototyping & Volume

Manufacturing

Silitronics offers agile prototyping—delivering functional substrates fast—alongside robust volume manufacturing, maintaining process repeatability, high yield, and rigorous documentation from the first sample to full-scale deployment.

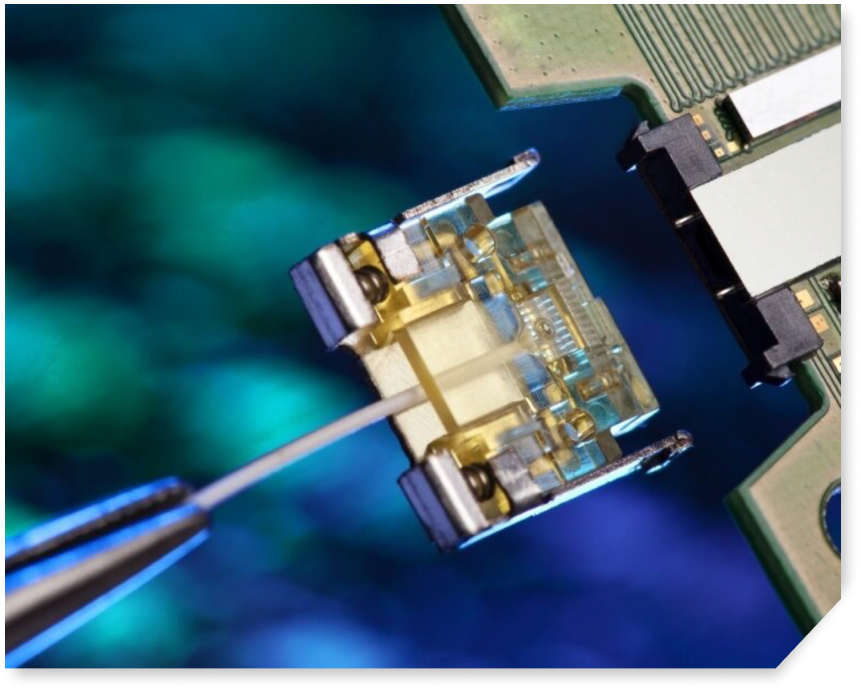

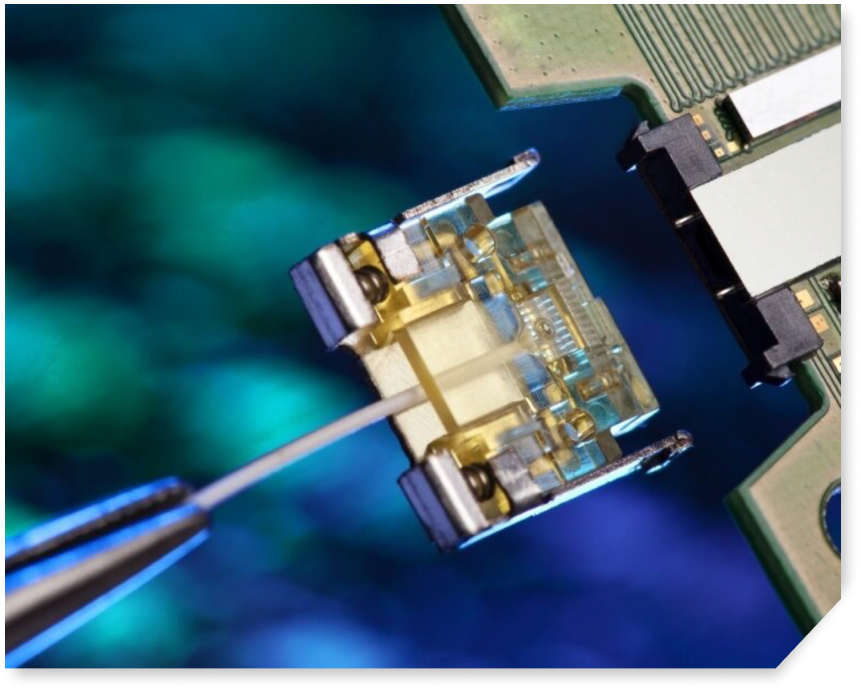

Silicon Photonics

Powering the Future at the Speed of Light with Photonics

Silicon Photonics is transforming high-speed computing, AI clusters, and next-gen data transfer. Our expertise in sub-micron active alignment, optical integration, and high-bandwidth packaging ensures low-latency, energy-efficient performance. From LiDAR to AI-driven interconnects, we deliver cutting-edge photonics solutions that push the limits of speed, scalability, and efficiency.

LEARN MOREFabrication Services Spectrum

Organic Build-Up Substrates

High-speed multilayer build-up substrates with fine line/space, thin core, and embedded passives. Silitronics provides full customization for networking, AI, and medical platforms, ensuring superior signal integrity and thermal handling, from rapid prototyping to high-volume production.

Ceramic Substrates (Etch Thick Film, HTCC, LTCC)

Our state-of-the-art fabrication facility delivers high-precision multi-layer substrates tailored for AI, HPC, and Silicon Photonics. With expertise in organic and ceramic substrates, fine-pitch interconnects, and high-density integration, we ensure superior reliability, scalability, and manufacturing excellence. From prototypes to high-volume production, we bring innovation to life with precision.

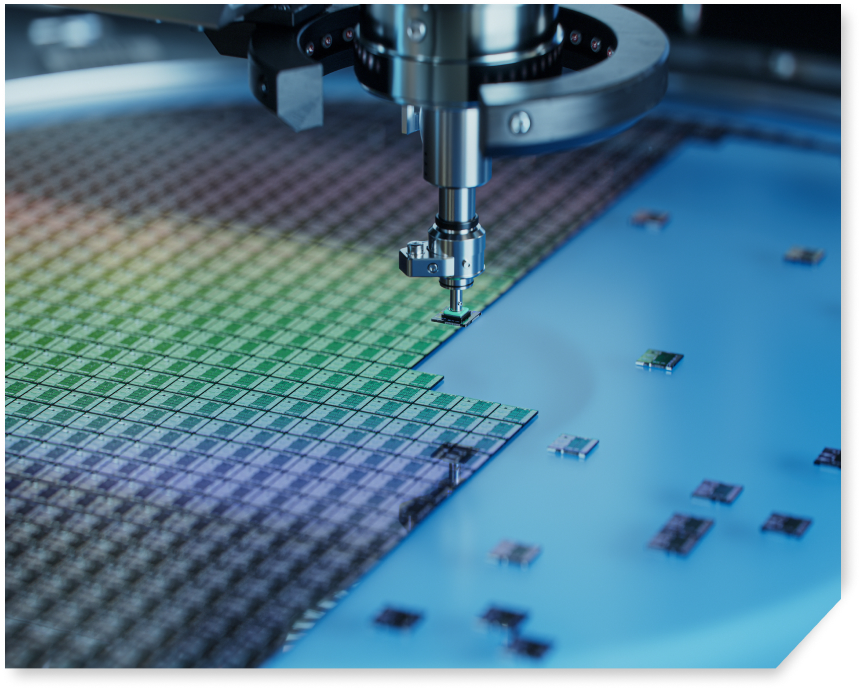

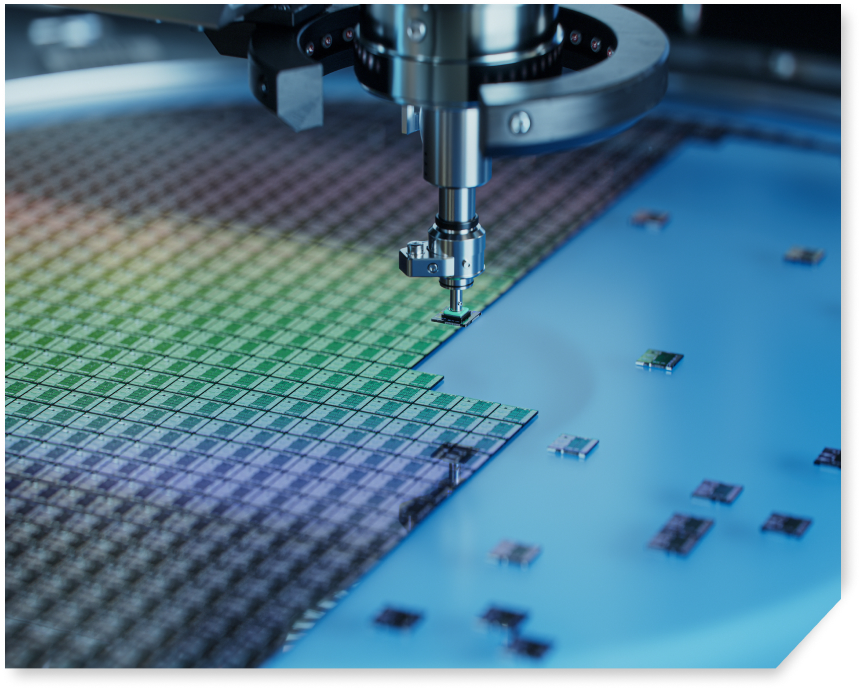

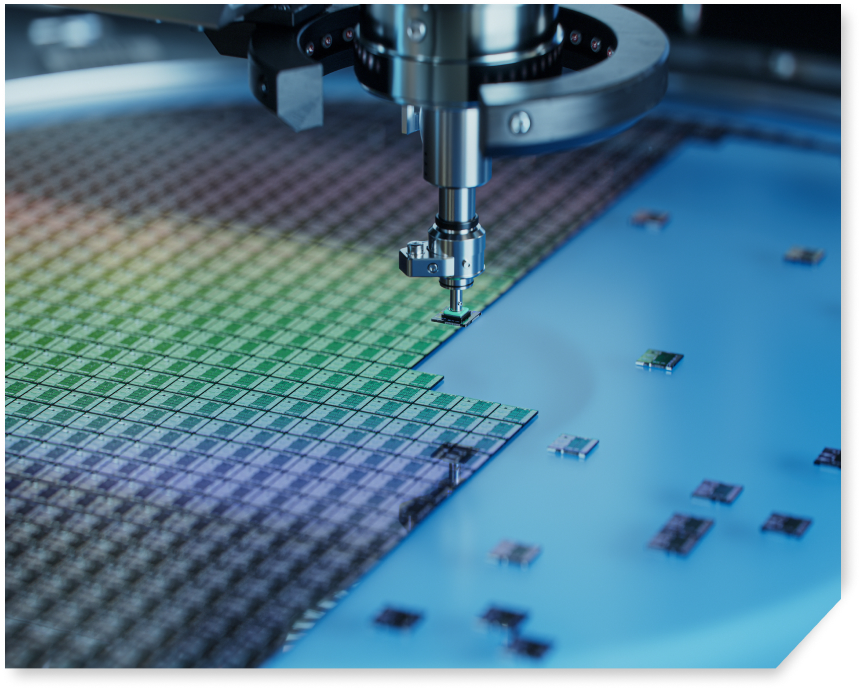

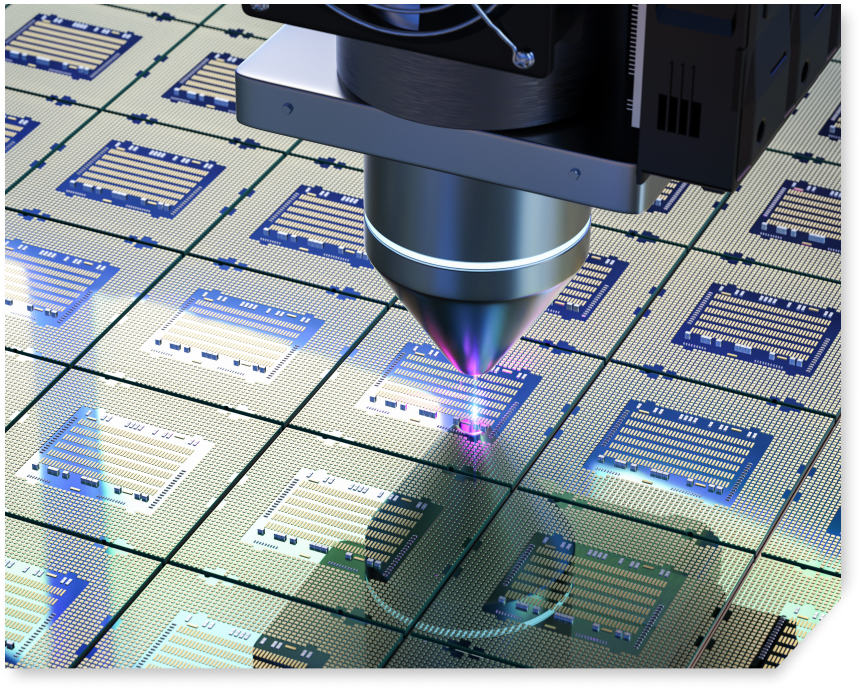

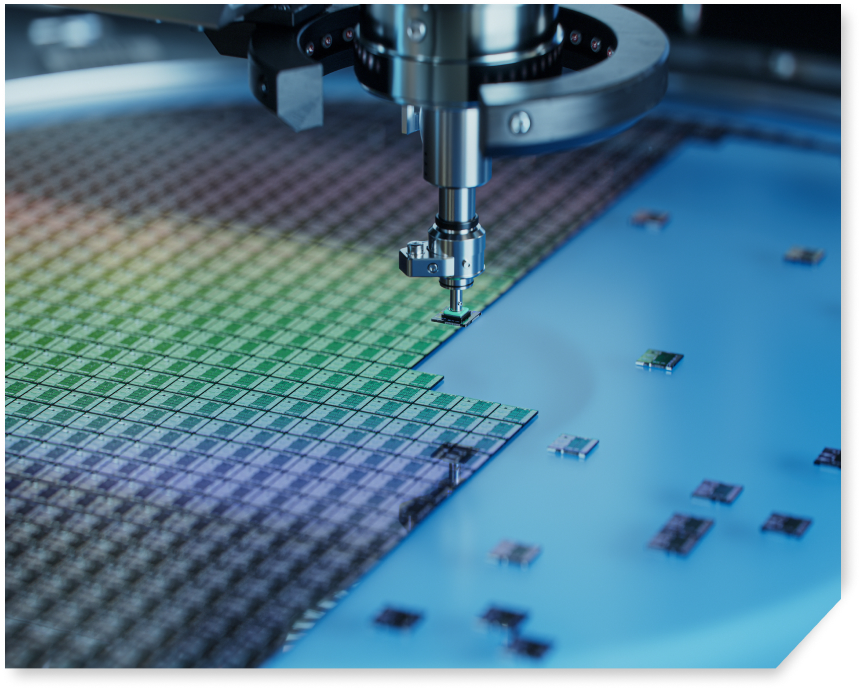

Dicing

High-Precision Wafer Dicing

Specializing in robust ceramics for wireless, sensor, and RF applications. Employing advanced tape lamination and metallization processes, Silitronics delivers ceramics with precise conductor layouts, superior environmental resilience, and polished surfaces for optimum device performance.

HDI & Fine-Pitch Substrate Design

State-of-the-art microvia, blind/buried via, and tightly controlled copper thickness enablenext-gen integration for silicon photonics, SiP, and multichip modules. Designed for high reliability, superior SI/PI, and production scalability.

Rapid Prototyping & Volume Manufacturing

Silitronics offers agile prototyping—delivering functional substrates fast—alongside robust volume manufacturing, maintaining process repeatability, high yield, and rigorous documentation from the first sample to full-scale deployment.

Our Services Spectrum

Precision-Driven Design for

Next-Gen Semiconductor &

Photonic Packaging

From concept to layout, our advanced design expertise ensures seamless integration of chips, substrates, and interconnects. We optimize signal integrity, power efficiency, and thermal performance to meet the demands of AI accelerators, quantum computing, and high-speed photonic systems. With deep engineering insights, we design scalable, high-reliability solutions for the future.

LEARN MORE

Fabrication for Advanced

Semiconductor & Photonic Packaging

Our state-of-the-art fabrication facility delivers high-precision multi-layer substrates tailored for AI, HPC, and Silicon Photonics. With expertise in organic and ceramic substrates, fine-pitch interconnects, and high-density integration, we ensure superior reliability, scalability, and manufacturing excellence. From prototypes to high-volume production, we bring innovation to life with precision.

LEARN MORE

High-Precision Wafer Dicing

We deliver advanced wafer dicing using precision blade and laser technologies to ensure clean die separation with minimal chipping. Optimized for high yield and low particle contamination, our dicing supports next-gen semiconductor packaging and performance.

LEARN MORE

Powering the Future at the

Speed of Light with Photonics

Silicon Photonics is transforming high-speed computing, AI clusters, and next-gen data transfer. Our expertise in sub-micron active alignment, optical integration, and high-bandwidth packaging ensures low-latency, energy-efficient performance. From LiDAR to AI-driven interconnects, we deliver cutting-edge photonics solutions that push the limits of speed, scalability, and efficiency.

LEARN MORE

Seamless Assembly for High-Precision

Semiconductor & Photonic Packaging

Our cutting-edge assembly expertise ensures precise chip-to-package integration with industry-leading sub-micron active alignment, high-density interconnects, and heterogeneous integration. We specialize in complex optical and electronic assemblies for AI accelerators, 5G networks, and next-gen computing, delivering high-reliability solutions that optimize performance and reduce time to market.

LEARN MORE

Breakthrough Chiplet Integration for

Scalable, Next-Gen Systems

Silitronics empowers the future of electronics with advanced chiplet integration—merging diverse dies on precision-engineered interposers for optimal signal, power, and thermal performance. Our expertise in modular floor planning and heterogeneous assembly accelerates high-bandwidth, low-latency connectivity that’s essential for AI, HPC, and 5G. From concept design to rigorous validation, Silitronics helps customers bring complex systems to market—faster, smarter, and more reliably.

LEARN MOREOur Services Spectrum

Precision-Driven Design for

Next-Gen Semiconductor

& Photonic

Packaging

From concept to layout, our advanced design expertise ensures seamless integration of chips, substrates, and interconnects. We optimize signal integrity, power efficiency, and thermal performance to meet the demands of AI accelerators, quantum computing, and high-speed photonic systems. With deep engineering insights, we design scalable, high-reliability solutions for the future.

LEARN MORE

Fabrication for AdvancedSemiconductor & Photonic Packaging

Our state-of-the-art fabrication facility delivers high-precision multi-layer substrates tailored for AI, HPC, and Silicon Photonics. With expertise in organic and ceramic substrates, fine-pitch interconnects, and high-density integration, we ensure superior reliability, scalability, and manufacturing excellence. From prototypes to high-volume production, we bring innovation to life with precision.

LEARN MORE

High-Precision Wafer Dicing

We deliver advanced wafer dicing using precision blade and laser technologies to ensure clean die separation with minimal chipping. Optimized for high yield and low particle contamination, our dicing supports next-gen semiconductor packaging and performance.

LEARN MORE

Powering the Future at the Speed of Light with Photonics

Silicon Photonics is transforming high-speed computing, AI clusters, and next-gen data transfer. Our expertise in sub-micron active alignment, optical integration, and high-bandwidth packaging ensures low-latency, energy-efficient performance. From LiDAR to AI-driven interconnects, we deliver cutting-edge photonics solutions that push the limits of speed, scalability, and efficiency.

LEARN MORE

Seamless Assembly for High-Precision Semiconductor & Photonic Packaging

Our cutting-edge assembly expertise ensures precise chip-to-package integration with industry-leading sub-micron active alignment, high-density interconnects, and heterogeneous integration. We specialize in complex optical and electronic assemblies for AI accelerators, 5G networks, and next-gen computing, delivering high-reliability solutions that optimize performance and reduce time to market.

LEARN MORE

Breakthrough Chiplet Integration for Scalable, Next-Gen Systems

Silitronics empowers the future of electronics with advanced chiplet integration—merging diverse dies on precision-engineered interposers for optimal signal, power, and thermal performance. Our expertise in modular floor planning and heterogeneous assembly accelerates high-bandwidth, low-latency connectivity that’s essential for AI, HPC, and 5G. From concept design to rigorous validation, Silitronics helps customers bring complex systems to market—faster, smarter, and more reliably.

LEARN MORECase Studies

Flawless execution, rapid prototyping, and first-pass success for cutting-edge automotive LiDAR technology.

Flawless execution, rapid prototyping, and first-pass success for cutting-edge automotive LiDAR technology.

Download case studyAccelerating Innovation in 4K Live Streaming & Gaming Cameras

First-pass success, rapid prototyping, and precision execution for breakthrough imaging technology.

Download case studyHigh-Yield, High-Precision IC Packaging for 5G & RF Innovation

Reliable, flexible, and high-performance IC packaging solutions, ensuring uninterrupted supply and exceptional quality.

Download case studyGet in touch

Interested in our end-to-end advanced semiconductor and photonics (PIC) packaging solutions?

Share your details for an expert connect.